The Panasonic Power Choke Coils have top level industry features.

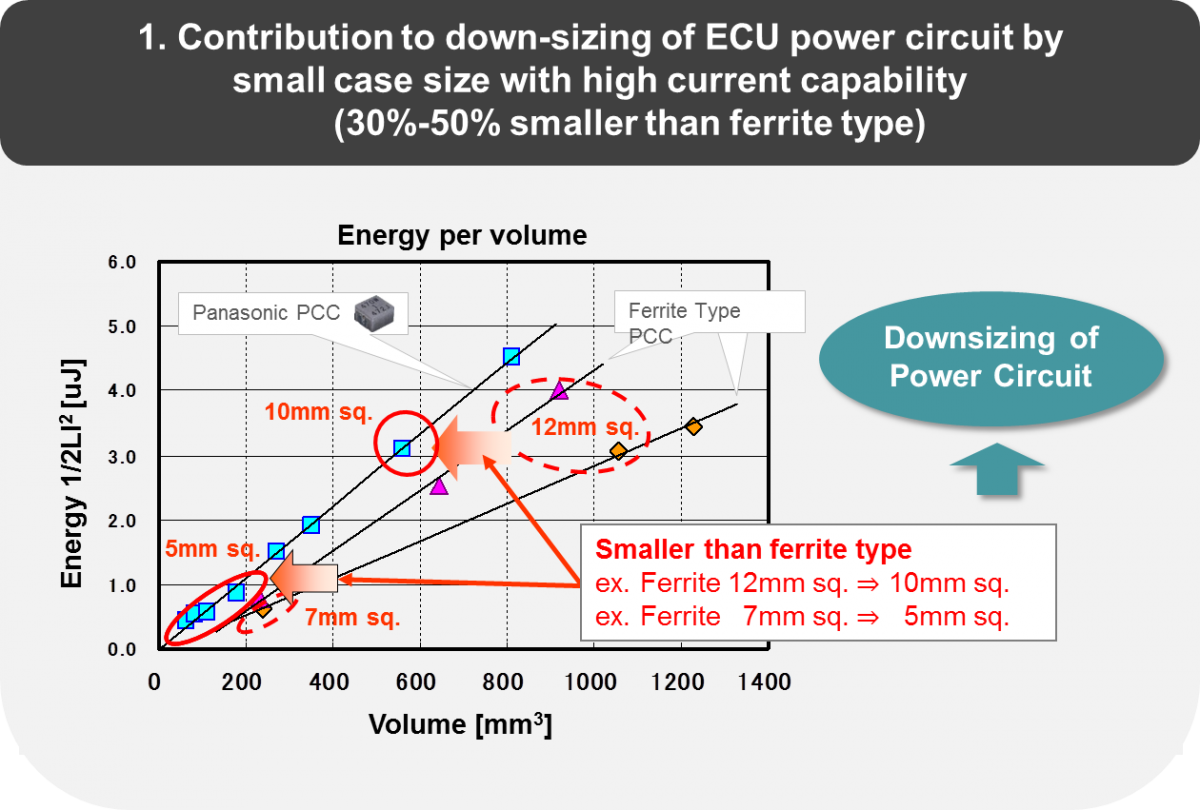

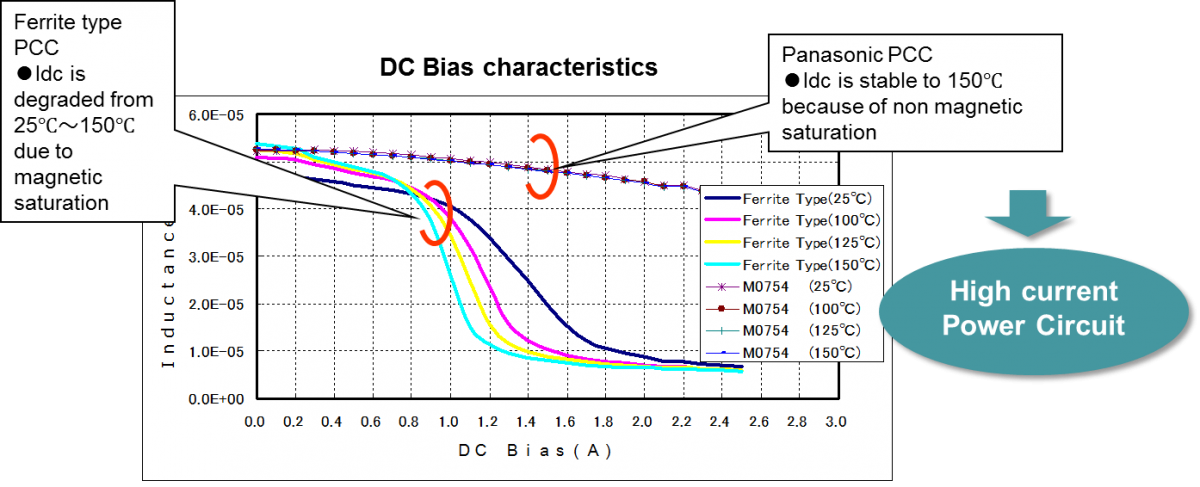

1. Contribution to down-sizing of ECU power circuit by small case size with higher current capability.

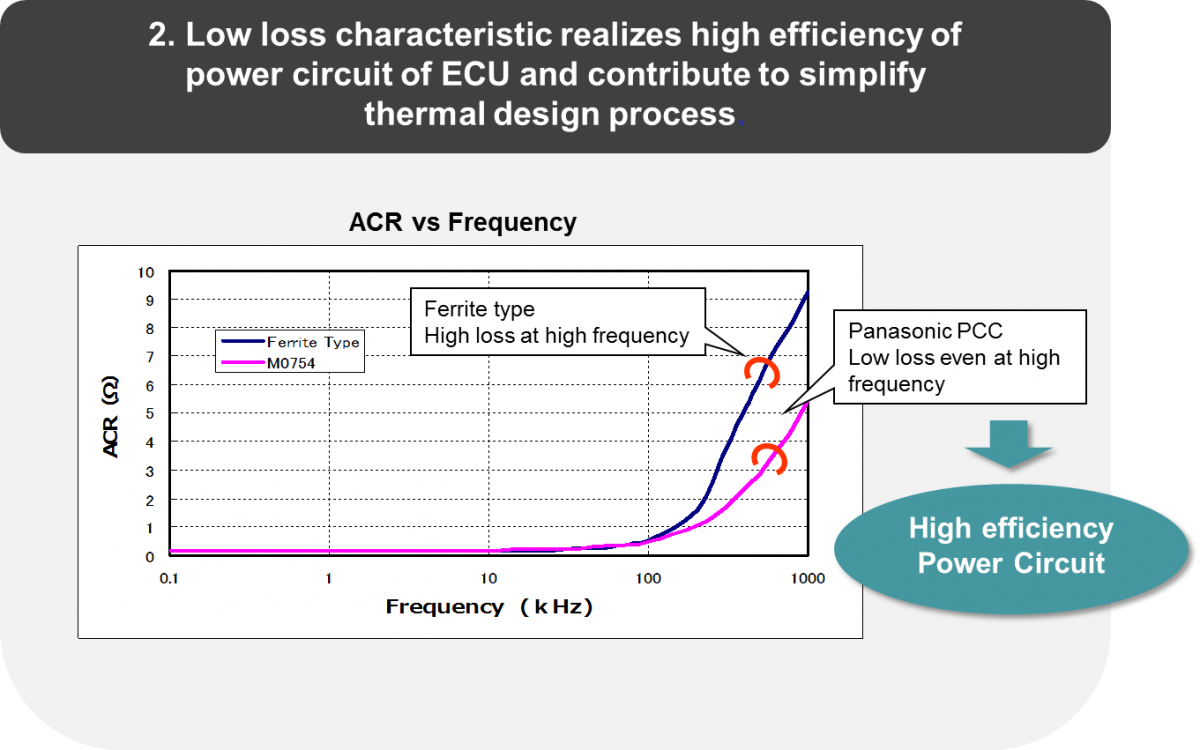

2. Low loss characteristic realizes high efficiency of power circuit of ECU and contribute to simplify thermal design process.

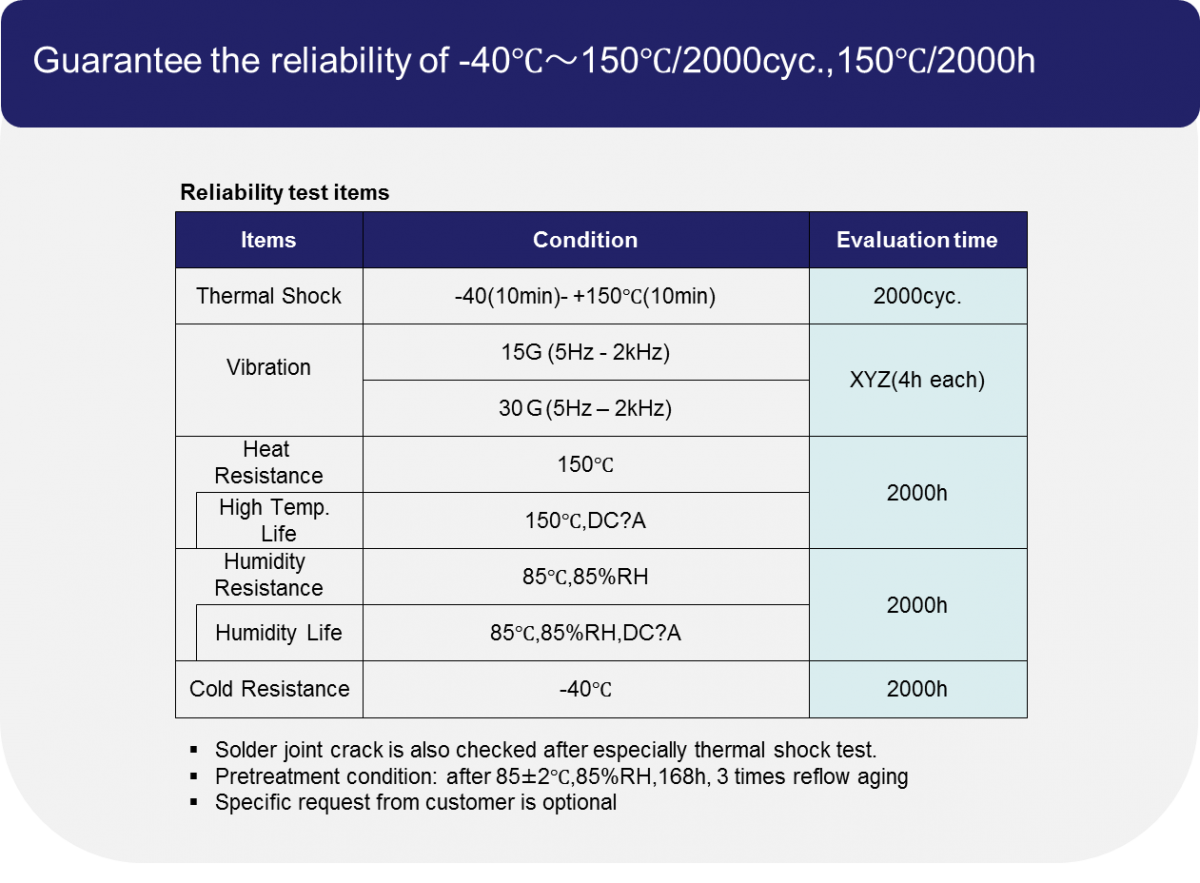

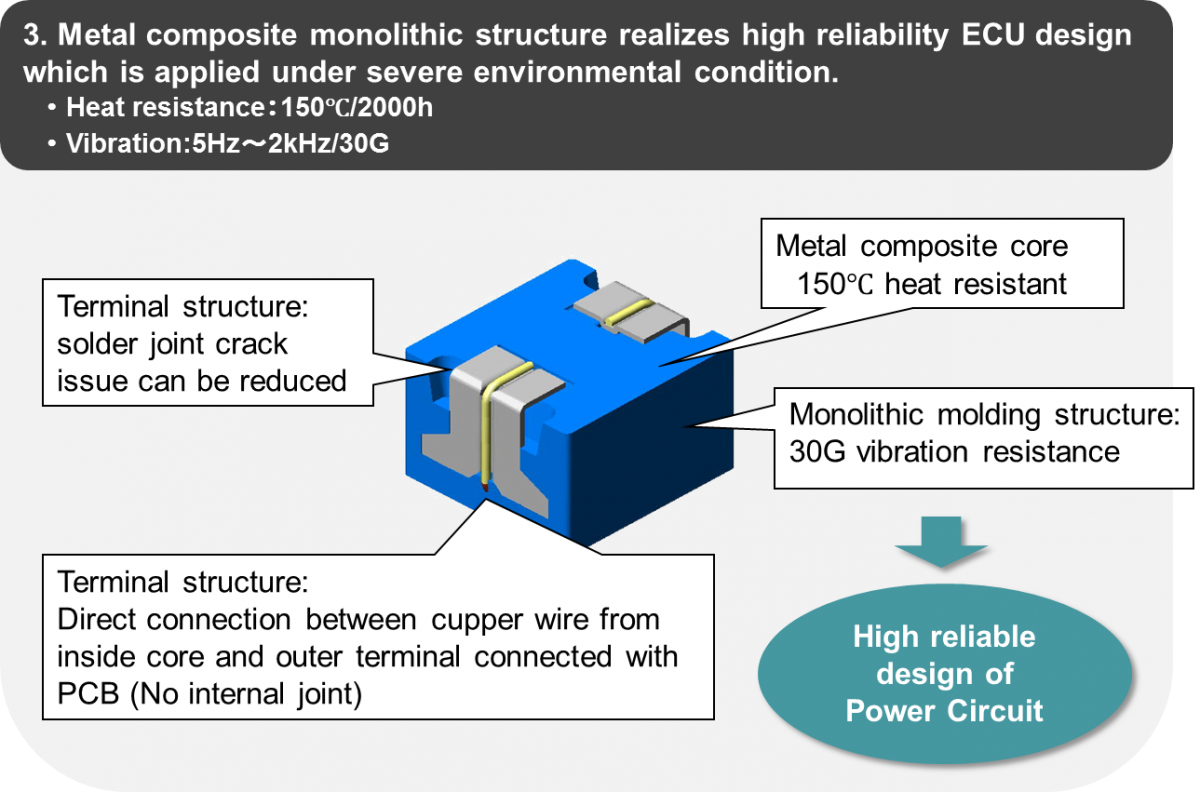

3. Metal composite monolithic structure realizes high reliability ECU design which is applied under severe environmental condition.

・Heat resistance:150℃/2000h

・Vibration:5Hz~2kHz/30G

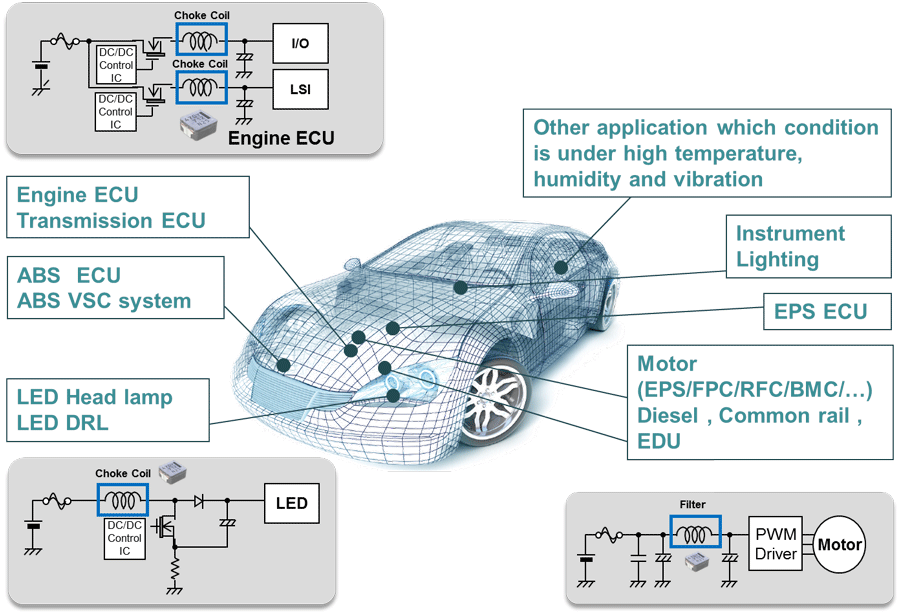

What is a Power Choke Coil (PCC)?

A Power Inductor for DC/DC converter, filter of ECU power circuit

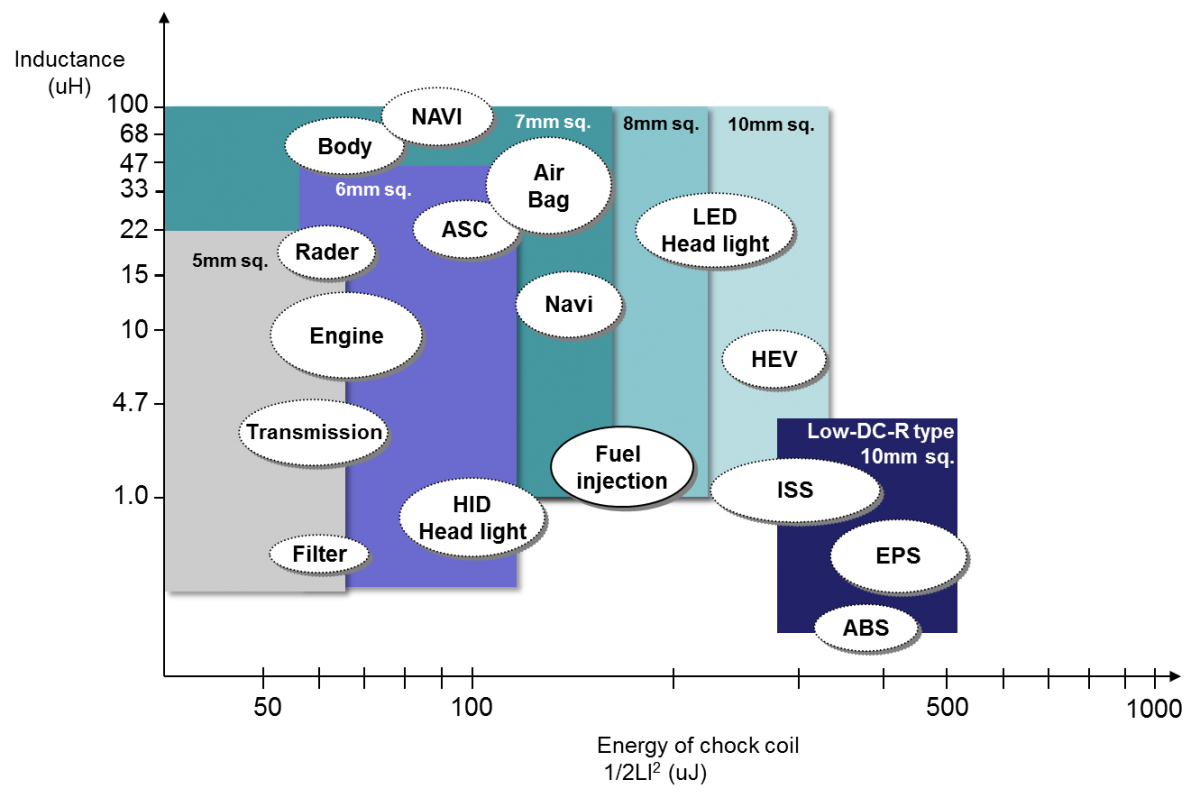

Features

Application by Line-Up

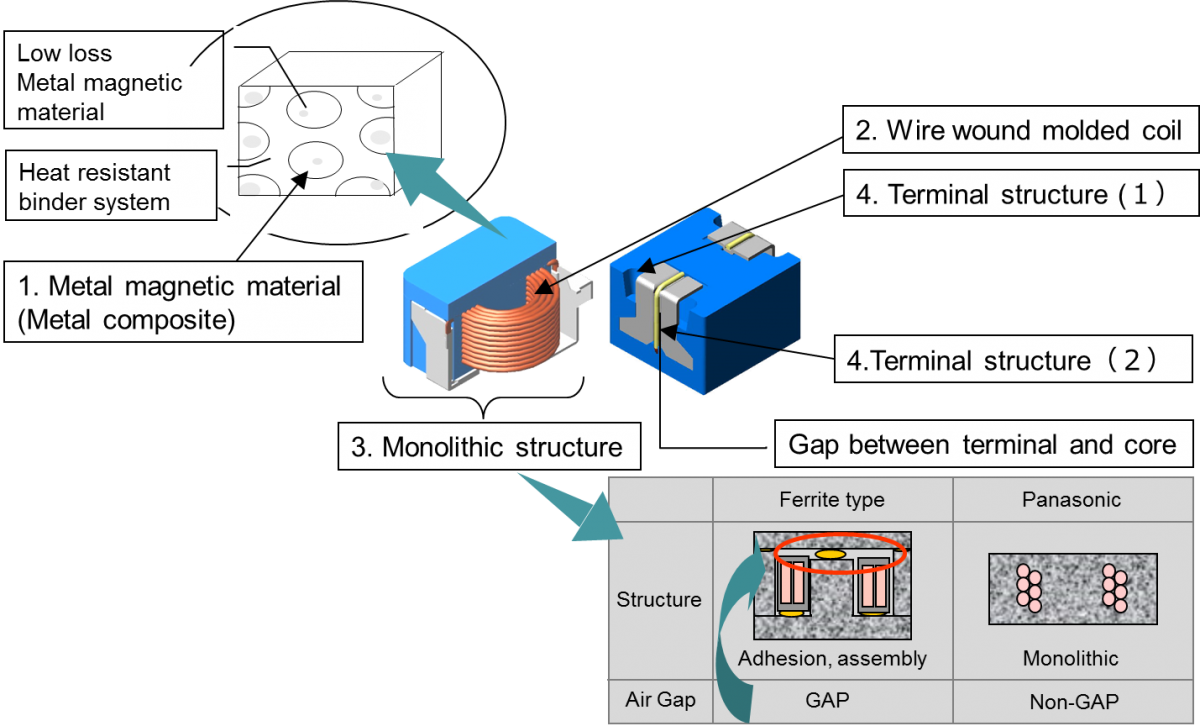

The Core Technology

The unique core technology which realizes “Top level high reliability “ in the industry:

1. Metal magnetic material (Metal composite)

Developed magnetic material which has high saturation magnetic flux density and low loss characteristic at high frequency.

2. Wire wound molding coil

Wire wound molding coil realizes smaller case size with high inductance value.

3. Monolithic structure

Monolithic structure of metal magnetic material and winding wire realizes vibration resistance.

4. Terminal structure

(1) Gap structure between backside of terminal and core can reduce solder joint crack issue due to thermal stress

(2) Unique terminal structure which has no internal joint can realizes superior vibration resistance.

Standard Reliability Test